Broke Handling

Broke roll handling covers the entire process of dismantling wrapped or unwrapped rolls and feeding the material gradually to the pulper. Broke roll line is used, not only for recycling damaged rolls, but also for ensuring the consistency of the pulp.

Raumaster Paper’s broke handling line includes automatic functions for:

Conveying systems

De-wrapping

Header removal

Plug removal

Roll cutting

Pulper infeed

Core collecting

Roll Cutter – Recycling made operator-friendly

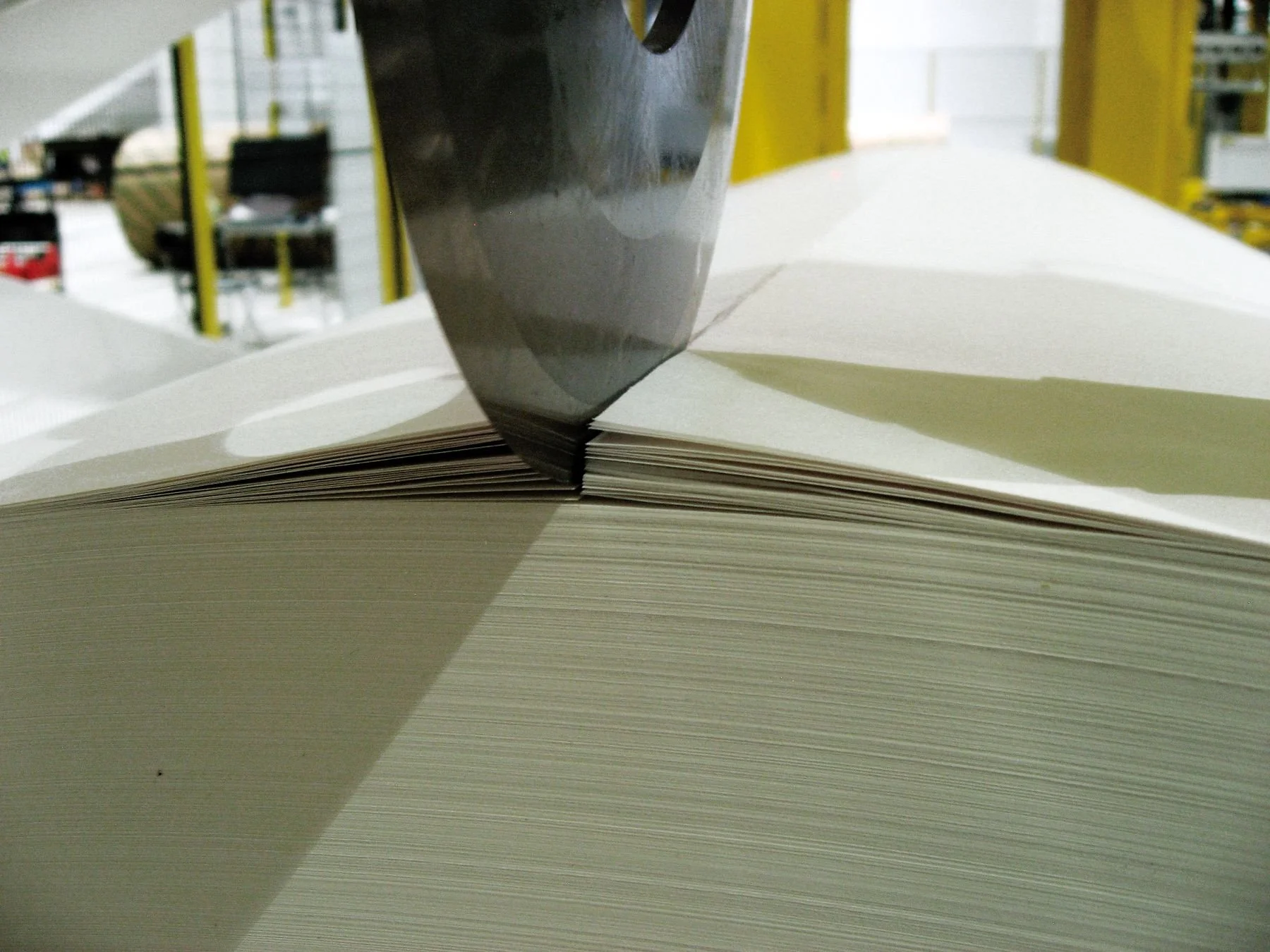

The function of roll cutter is to decrease waste material and contribute to the pulping process. Our cutting technique guarantees a constant infeed into the pulper which allows for smoother reprocessing with less energy consumption. It also protects the cores from damage thus facilitating re-use of cores, which leads to savings in raw material. The automatic core removal adds considerably to operator safety. We also offer solutions for the re-use of plugs and wrapping material.

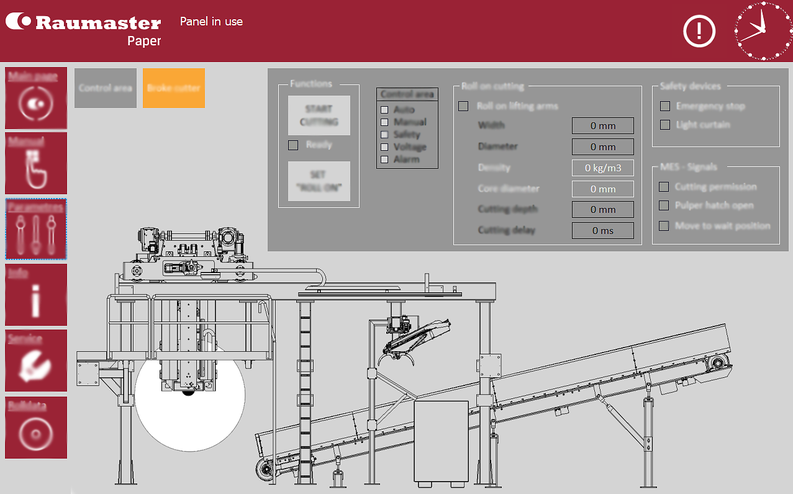

Our clients have been particularly satisfied with our user-friendly operator interfaces. They feature clearly visualized device pages and helpful sequence and troubleshooting data. If required, roll identification may be included into the link to MES.

Cutting parameters are program-controlled to achieve a steady material flow to the pulper.