Core Handling

Our core cutters meet the highest requirements

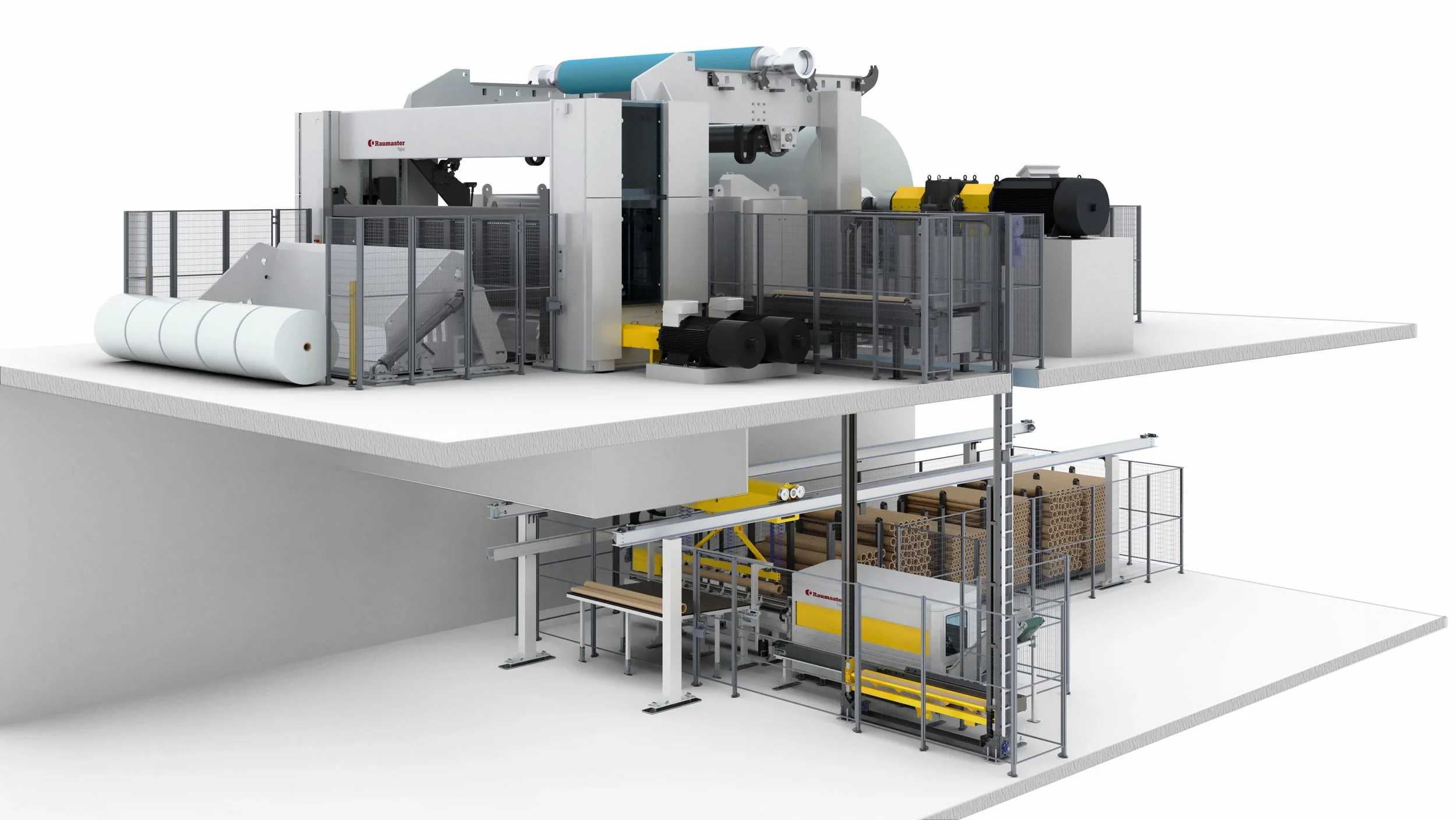

Our automatic core handling systems include entire process from parent core storage to accurate sized core infeed to the winder.

Additional solutions for parent core handling:

Core hoppers

Portal robots

Plug insertion

Core transfer

Core Cutter – Market-Leading Accuracy

Our core cutters meet the highest requirements. They provide the best cutting accuracy on the market combined with correct core lengths. The patented CleanCut technique guaranties smooth core ends with extremely low dust formation, especially into the inner core. Due to infeed technique one single cutter suffices for all core diameters.

CleanCut

Uneven or burred core ends may lead to wind-up problems, not to mention inaccurate core length. Core cutters by Raumaster Paper are designed to eliminate these issues, thus offering a smoother interaction between core preparation and winder.

The answer to miscuts is our patented CleanCut technique. This principle of blade rotation provides burrless, even and smooth roll ends with the best cutting accuracy on the market. Dust-free inner cores and surroundings complement the flawless end product.

Light Maintenance

A high amount of maintenance-free equipment makes our core cutters easy to maintain. When equipped with diamond blades, the replacement frequency of the blade may be significantly extended. The dust filter comes with a fire prevention system.

Greener

Option for waste management: core residual converted into fueling briquettes

One single cutter for all core diameters (3”–12”)

Smarter

Smooth core ends thanks to patented CleanCut technique

Best accuracy on the market

High functionality with easy-to-use interface

Cutting ans control parameters fully peremeterized

Comprehensive and clear trouble-shooting

Safer

Low level of maintenance – low blade replacement frequency when equipped with diamond blades

Fire prevention system for dust filter