Upgrades & Modernizations

Keeping the Pace

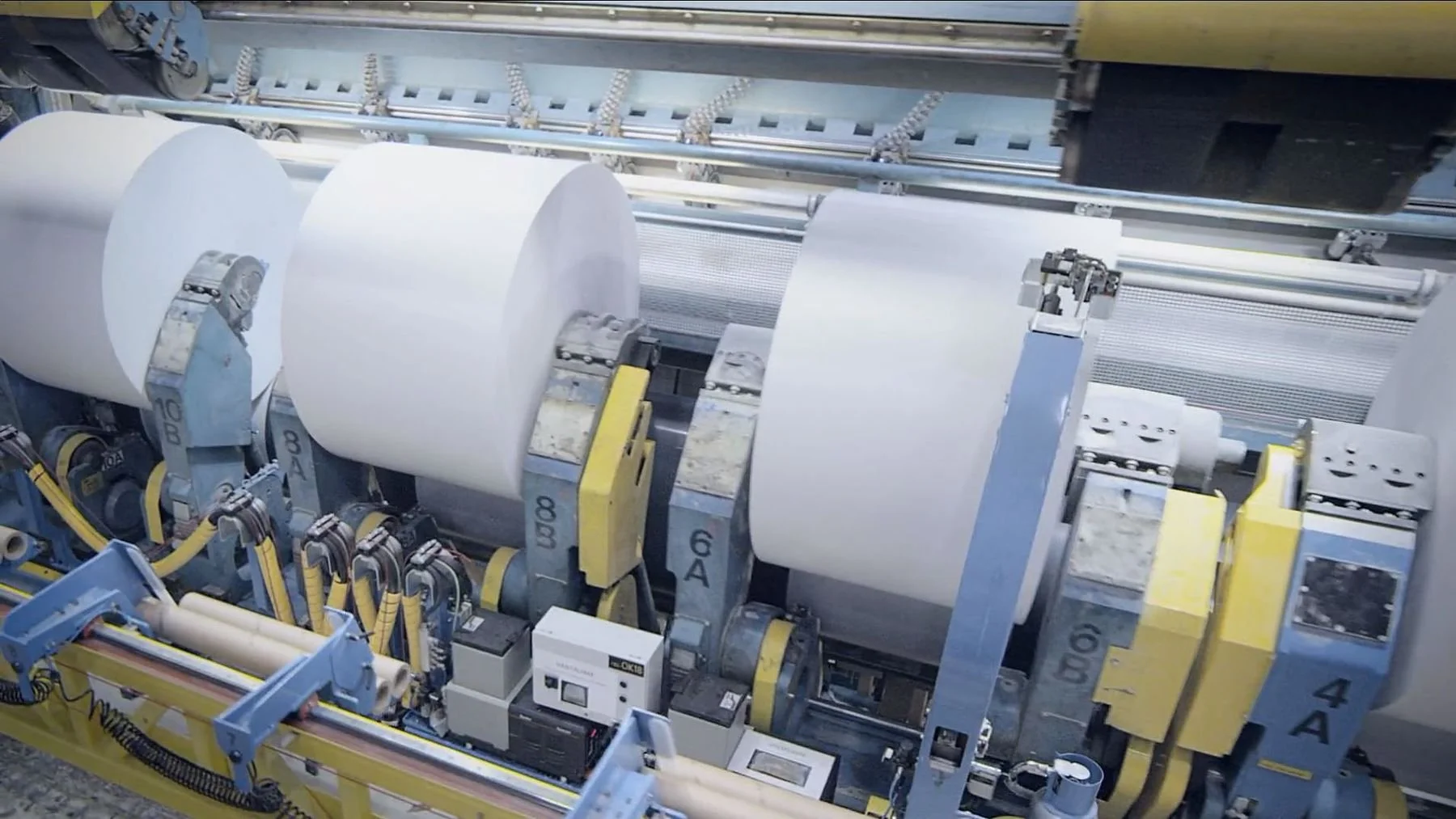

Paper finishing equipment are long time investments designed to operate profitably even over decades. Thorough maintenance is required to preserve functionality, but every now and then, to keep pace with evolution, updates to the existing equipment are needed. Modernizations and rebuilds enable mills to increase productivity and efficiency and – as its best – achieve significant capacity increase.

Raumaster Paper has considerable experience in modernization works. Our expertise covers the whole paper finishing product assortment, irrespective of their original manufacturer. Thanks to our own comprehensive product offering we are able to deliver solutions beneficial for your entire paper finishing process.

We offer:

partial or entire system rebuilds incl. engineering

integration of new equipment (mechanical and automation)

safety upgrades

increase of level of automation

optimization of processes and capacity

removal of bottlenecks and sources of roll defects

system and product adaption (eg. growing roll size)

Renewed core and end gluing as a part of control system, set change and safety upgrade.

Automation upgrades enhance usability and safety.

Safety Upgrades

Every Project is a Safety Project

As the requirements of machine safety standards increase, customers’ equipment also requires updating or rebuilding. Especially whenever an old machine is modified, it is also strongly associated with upgrading the safety level. In the industry, all equipment cannot be made completely safe, but the safety level is upgraded as high as current technical solutions allow. Raumaster Paper’s team also makes safety level upgrades and rebuilds for other manufacturers’ equipment. Safety upgrade always means that operators have to learn new working methods to operate with new safety devices. Therefore, we want to ensure that the new features are understood by allocating time for personnel training.

Our Safety Standards are World-Class

Raumaster Paper is proud to be part of the Finnish Institute of Occupational Health’s Zero Accidents Forum. The company was among the 122 workplaces that received the Institute’s safety level classification in 2024. This classification is awarded to member workplaces that have invested in the continuous improvement of occupational safety, with criteria developed in collaboration with Forum members. Raumaster Paper achieved the highest-level classification, ‘World Leader,’ simultaneously reaching the goal of zero accidents. “It is important that we have succeeded in achieving the goals we set together. We always approach safety issues from the perspective of our customers, subcontractors, and our own staff. We continue to work to improve safety and aim to be a leading promoter of occupational health and safety now and in the future,” says Pekka Leino, CEO of Raumaster Paper Oy.

One of the recent developments at Raumaster Paper has been the introduction of an electronic recording system for personal risk assessments. Personnel are requested to complete their site and workshop assessments via a cell phone application that feeds the data into the company’s information system.

Raumaster Paper has repeatedly received the Institute’s safety classification and aims to continuously improve and develop its safety culture. The Zero Accidents Forum has more than 560 company members nationwide, with the goal of uniting Finnish workplaces in the cause of occupational health and safety and working together for