Paper & Board Finishing

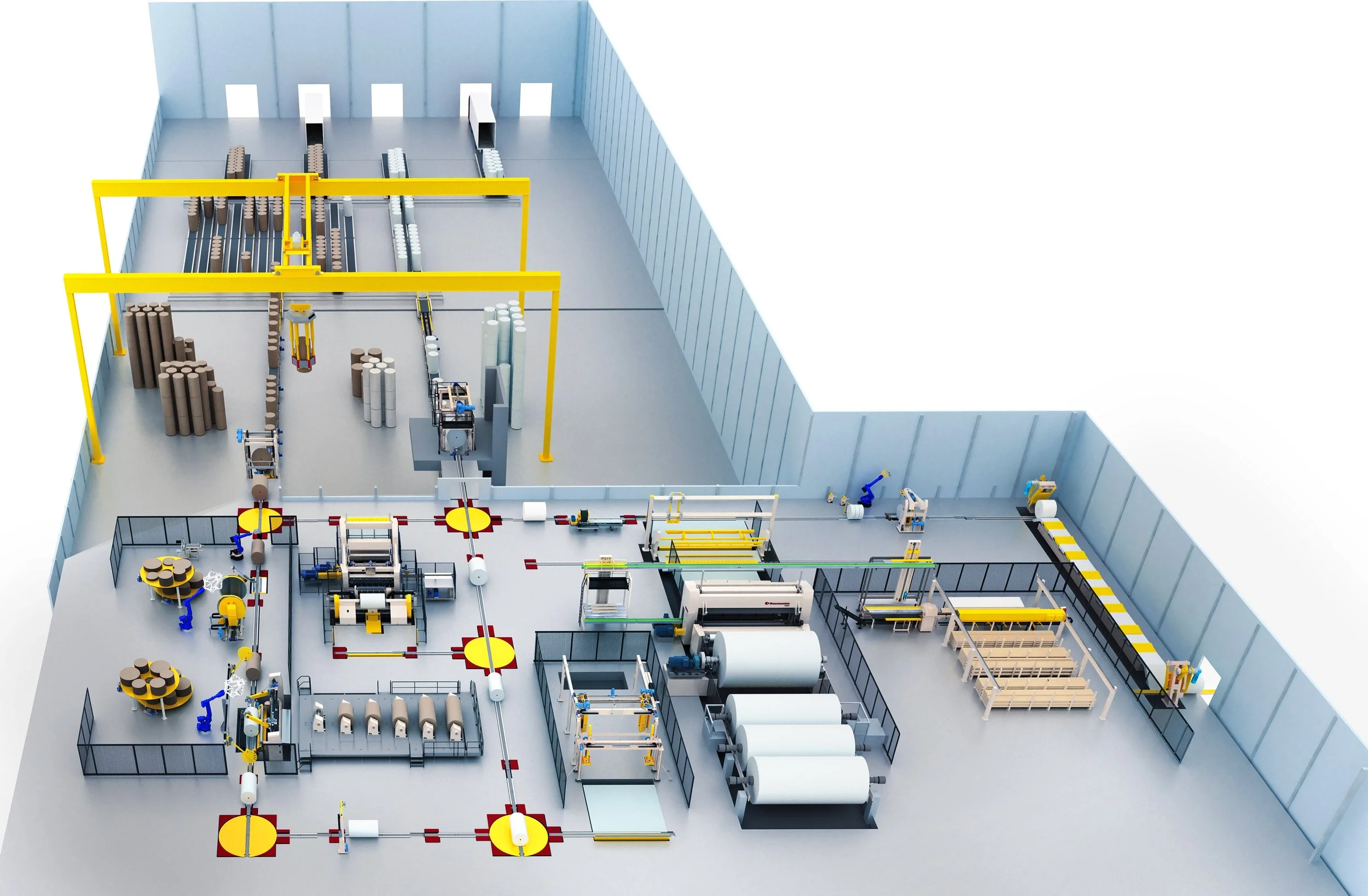

With decades of experience in layout planning, this is where Raumaster Paper’s core competence lies. We produce tailored solutions with equipment adapting customers premises, production flow, maintenance routes and personnel safety.

Raumaster Paper´s conveyor products may be integrated into all paper finishing systems and can be adapted to all roll sizes. Our vertical conveyors, upenders, stoppers, turntables and other devices are capable of handling all diameters, from the narrowest customer rolls until the largest and heaviest jumbo rolls.

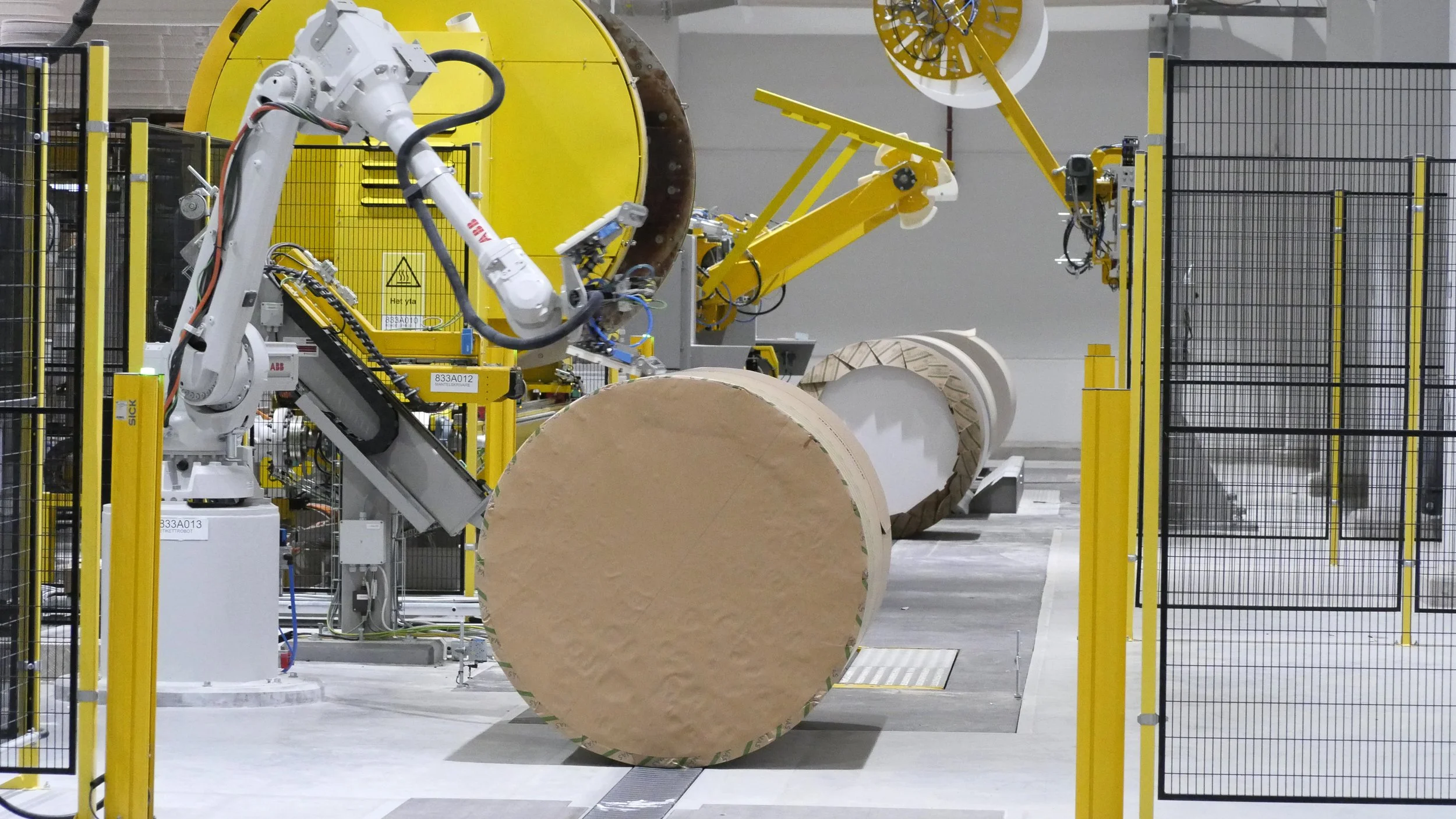

Raumaster Paper wrapping systems are modular and applicable for all roll sizes and capacities ranging from 30 to 180 rolls per hour. Radial and axial wrapping methods are possible applying plastic, stretch film, kraft or a combination of materials. Our solutions provide optimal protection against climatic, environmental and mechanical stress.

Staying on top of development

-

Our systems are designed for maximum life-cycle and optimized energy consumption with efficient drive choices and the option for energy recovery. We aim for less use of greases by means of maintenance-free bearings and other components wherever possible. Food grade lubricants are adaptable. Since the introduction of our hydraulic-free lowering upender, our conveying systems have been practically hydraulic-free thus bringing heavy duty equipment on an entirely new level of sustainable operation.

-

Our products are always delivered with complete state-of-the-art safety equipment engineered on the basis of dedicated risk analysis. We deliver device-specific instructions and safety trainings by our specialists. A high level of automation and maintenance-free spare parts add to operator safety.

-

Our systems are fully automated with operator-friendly interfaces. They feature individual device status pages with clear visualization and design. Diagnostics are available for operators and maintenance personnel, which our clients have praised to significantly fasten problem solving. All our system solutions are factory acceptance tested prior to delivery.

Roll Handling

Conveyor systems is where Raumaster’s story began and where Raumaster Paper´s core competence still lies, even today. During nearly four decades in business, we have optimized our products to fulfill the highest demands: even after a long ride over miles of conveyors and with several handshakes – your rolls will reach their destination, safe and smooth.

Raumaster Paper´s conveyor products are always custom-made and perfectly tailored to suite our clients’ specific demands. They may be integrated into all paper finishing systems and can be adapted to all roll sizes. Our vertical conveyors, upenders, stoppers, turntables and other devices are capable of handling all diameters, from the narrowest customer rolls until the largest and heaviest jumbo rolls.

Roll Wrapping

We offer a wide range of roll wrapping systems for reliable and safe wrapping. Our solutions are modular and can thus be tailored to meet your specific need. They are applicable for all roll sizes and capacities ranging from 30 to 180 rolls per hour. Radial and axial wrapping methods are possible applying plastic, stretch film, kraft or a combination of materials. Our solutions provide optimal protection against climatic, environmental and mechanical stress.

Master product line

With its compact and straightforward design, the Master wrapping product family enables lower investment costs and reduces the need for floor space. All Master wrapping solutions can be easily integrated with existing roll handling systems, as complementary or bypass lines. When fully automated, Master Wrapping lines perform with a capacity of up to 80 rph featuring a. o. robotized header and label applications.

Modulwrap® product line

Raumaster Paper Modulwrap® wrapping lines are tailored to fit all premises and specific requirements. Each system can be automated to the required level - from basic manual machines to fully automated wrapping lines including graphical user interfaces with comprehensive diagnostics and process monitoring systems.

All wrapping lines are assembled and tested in our workshops to ensure high quality and quick installation and start up.