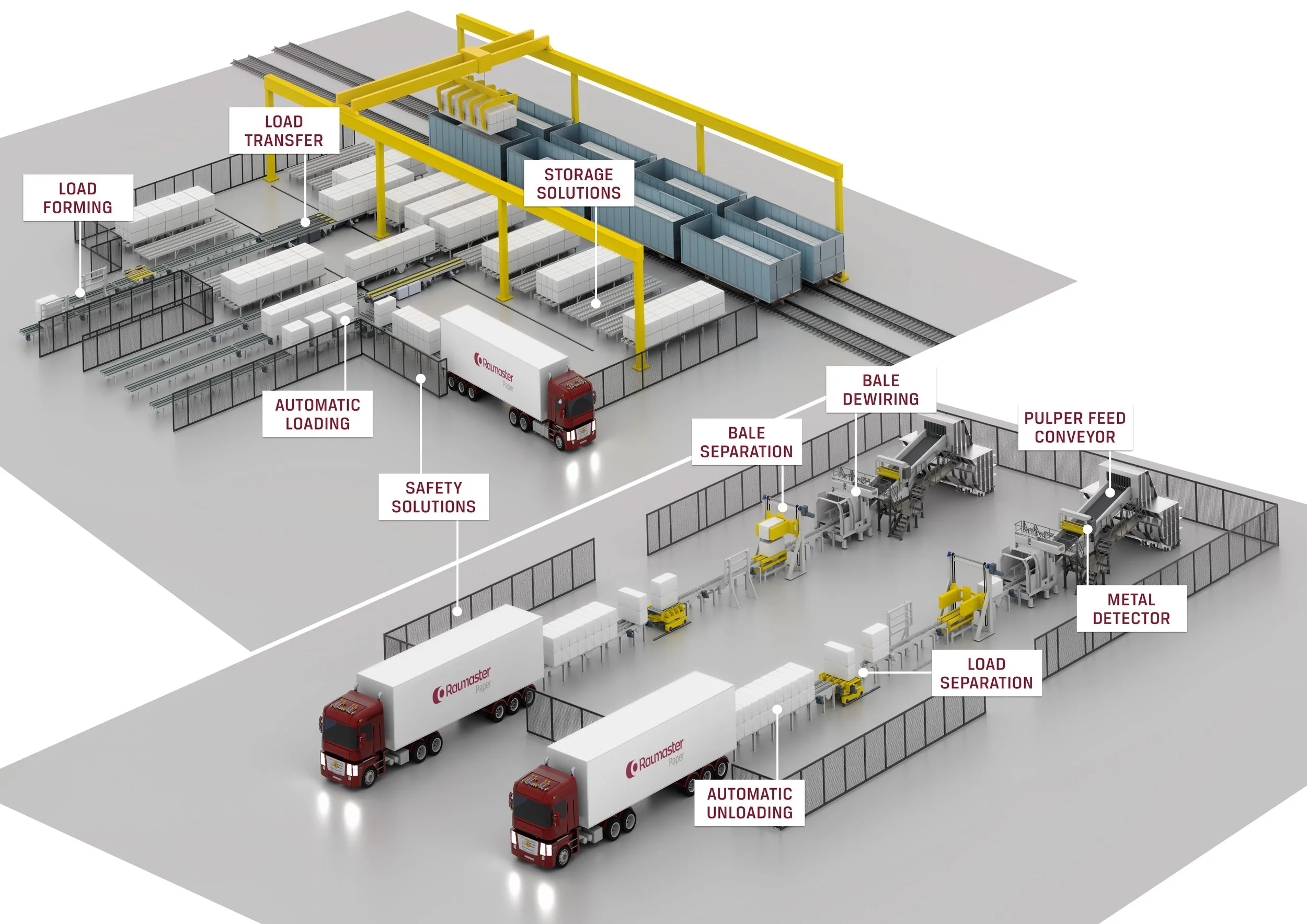

Pulp Bale & Roll Handling

Raumaster Paper bale handling is designed to preserve the pulp bale form throughout the transit process. Fully automated systems form bale loads according to the transportation requirements. Loads can be transferred to storage or to shipment uninterruptedly 24/7. These high-capacity systems do not damage the bales during handling and keep the personnel safe from loading areas.

Raumaster Paper bale handling benefitS

High safety level

Low emissions

High capacity

Less damaged bale waste

Uninterrupted operation 24/7

Streamline production

Raumaster Paper systems for pulper infeed include the entire process from unloading the pulp bales to feeding sheets to the pulper. Fully automated systems consist of conveying, load separation and bale stack unloading. Individual bales are conveyed through dewiring station and guided to the pulper feed conveyor. Automatic system also ensures that there are no impurities, such as metal wire pieces, conveyed to the pulper.

Pulp Roll Handling

Raumaster Paper’s core competence lies in roll handling. Whether the material is pulp, paper, board or tissue, our roll handling systems can be tailored to your product and adapted to different roll sizes.

See more about our solutions for core handling and roll cutters for pulper infeed in broke handling.